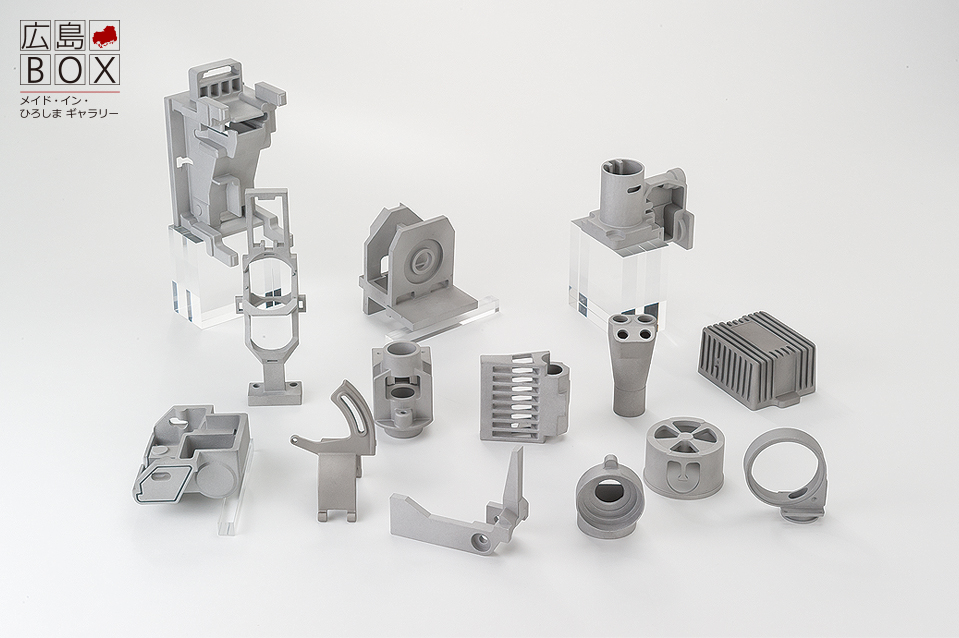

Lost wax precision casting partsKing Parts, Limited

| Exhibitor (Manufacturer) | King Parts, Limited |

|---|---|

| Address | 879-1 Shimoiwanari Miyuki-cho, Fukuyama City, Hiroshima |

| TEL | (084)955-3102 |

| Established | October 1, 1964 |

| Representative | Representative Director, President: Daiji Takahashi |

| Capital stock | 140,000,000 yen |

| Number of employees | 362 employees |

| Job description | Manufacture and sale of metal parts for precision devices in a variety of fields using the precision casting technique known as "lost wax casting |

| Website | http://www.kingparts.co.jp/en/dinfo/outline.php |

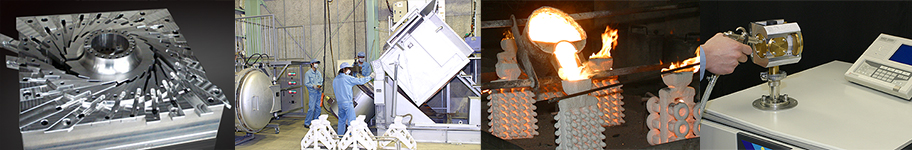

Established in 1964, we manufacture and sell precision equipment metal parts for various sectors, using a casting technique called “lost wax casting.” Our manufacturing processes are 100% controlled under an integrated production system with an in-house tool and die shop, foundry, and machining shop. This enables us to deliver finished products – including heat treated and surface treated products – in a short period of time, even though we manufacture a wide variety of products in small volume.

■Features of lost wax casting

・Even dies with intricate structures can be manufactured with high precision.

・Parts made from any kind of metal can be manufactured.

・Suitable for small lot production (even from a few pieces).

・Since the molding material is wax, the die making cost is low.(Only aluminum blocks are machined, requiring no hardening treatment.)

・Since the molding material is wax, dies do not deteriorate.

Left:Die design and manufacturing, Middle left & Middle right:Casting, Right:Quality test

A product family produced by the lost wax casting production method that made production of metal castings with complicated fine shapes possible. Lost wax castings support many fields including general industrial machinery, electronics, electrical, electric power machines, machine tools, medical equipment, rolling stock, aircraft, measuring instruments, tableware equipment, and defense equipment.